Applications Lubricants, oils and fuels

Absolute viscosities and interfacial properties – precisely measured according to international standards

The change in viscosity due to temperature fluctuations is of importance in those places where oils and liquids are produced, pumped, and moved. The minimization of friction losses due to the selection of suitable oils is essential when it comes to the design of machines and pneumatics. As mentioned before, capillary viscometry is the most precise and strictly standardized method to measure absolute viscosities. Measuring routines need to be executed efficiently, quickly, with absolute safety, and reproducibly at any time. With the modular concept of LAUDA Scientific, system configurations can be put together which combine the functionalities required for the respective purpose.

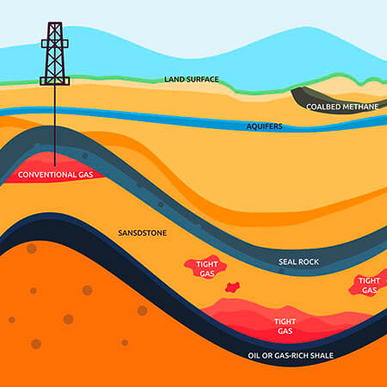

Important indicators of oil quality, for example, to check the deterioration of transformer oils, are also the surface tension (ST) to air, but particularly the interfacial tension (IT) to water or aqueous solutions. The surface/interfacial tension also serves to characterize additives for fuels and lubricants or to analyze tertiary crude oil production and all sorts of surfactants, e.g. emulsifiers, wetting agents, etc. Alongside the conventional lamellae tension methods of Du Noüy and Wilhelmy, LAUDA Scientific provides the drop volume and bubble pressure methods with which adsorption processes of amphiphilic additives or aging products can also dissolve over time on interfaces.

Viscosity index and kinematic viscosities of SAE/ISO motor oils

Recovery rate in tertiary oil production with surface active substances

Pumpability of crude oils (record of viscosity temperature characteristics)

Absolute, kinematic, and dynamic viscosities of highly viscous liquids

LAUDA Scientific Viscometer systems – Advantages and benefits at a glance

|

Advantages |

Benetfits |

|---|---|

|

ASTM D445 DIN 51562 Intuitive measuring principle Unrivalled precision Constant calibration not dependent on temperature Up to eight parallel measurement positions Compatibility |

Easy, affordable execution with stopwatch Better than 0.3 per cent guaranteed Only one capillary constant from -40 up to 200 °C Acceleration of the process International comparability independent of the measuring device |

|

Calculation of the viscosity index according to ASTM D 2270/ISO 2909 Automatic control of the temperature Extreme measurement range from -60 up to 200 °C |

Comparison of the specifications with current figures from the quality check Work-free periods can be used for long-term measurements Complete viscosity scan possible at all application temperatures |

LAUDA Scientific Tensiometer systems – Advantages and benefits at a glance

|

Advantages |

Benefits |

|---|---|

|

Sensitive to amphilic molecules Standardized sensors Ring method TD, interfacial tensions Drop volume method Computer software running Windows |

Low concentration of impurities, additives and aging products detectable International comparability Provide values in thermodynamic equilibrium Provides additional information on adsorption on interfaces Flexible experiment running, also for research tasks Intuitive operation, high degree of flexibility |